SMS code login

Password Login

Get SMS verification code

Get SMS verification code

2022-06-10

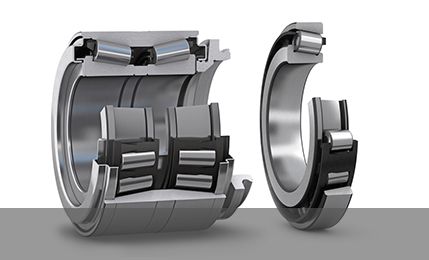

Common cage structures and materials of tapered roller bearings include:

1. steel pressed cage

Tapered roller bearings generally adopt steel pressed frame cages. This kind of cage is made of low-carbon steel plate through a series of cutting, forming and stamping processes. Stamping cage is processed by die, and the product has high precision and interchangeability. The cage has high efficiency in production and can reduce the manufacturing cost of products. This type of cage can be used in high temperature and harsh lubrication conditions.

2. polymer cage

Tapered roller bearing cages made of polymer materials are mainly used for lubricating and self sealing bearing components. Common polymer materials are reinforced with nylon thermoplastic and glass fiber. Polymer cages can be mass-produced with higher design flexibility than steel stamped cages. Polymer cages are lighter and easier to assemble in production. In some applications, one or two rolling elements can be added to improve the bearing load rating. However, there are requirements for the service temperature, which is generally not allowed to exceed 107℃.

3. machined cage

The machined cage of tapered roller bearing adopts reinforced design, which can be used under high-speed and heavy load conditions. Machined cage can be made of alloy steel by milling and reaming. It is easier to assemble the bearing with the cage, and the rolling element can be fixed by inserting the cage. According to the use requirements, additional oil holes can be added for lubrication. This kind of cage is rarely used.

4. pin cage

The tapered roller bearing pin type cage uses the pin in the center of the hollow roller to locate the rolling element. The pin type cage is composed of two cage rings and a pin welded and fixed on the other side of the thread on one side. This type of cage is mainly used for tapered roller bearings with large size sections (outer diameter greater than 400mm). Pin type cages are limited to low-speed applications (flange speeds below 20 m / s).